Tackling the tricky 5% of EDI projects

Introduction

Most new EDI projects are fairly straightforward to deliver providing the people involved are familiar with the technologies involved, and have a reasonable amount of experience.

95% of the time, the files are in EDI or XML format and are exchanged using well established methods like FTP, AS2 etc. This what most EDI/integration systems are designed to handle, so for these you can be pretty sure of a successful and cost-effective outcome using whatever EDI system your business has implemented.

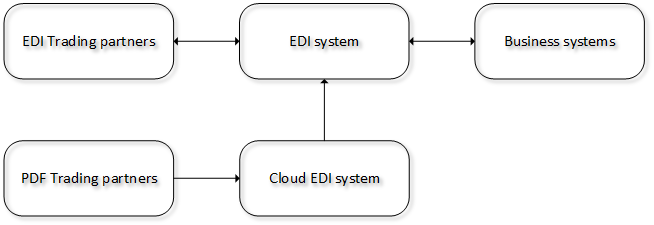

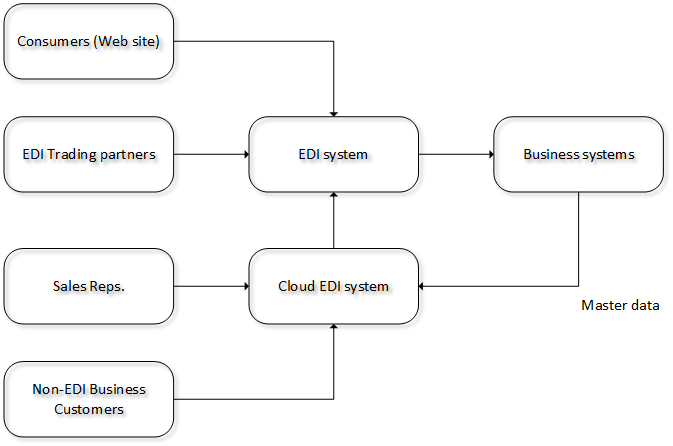

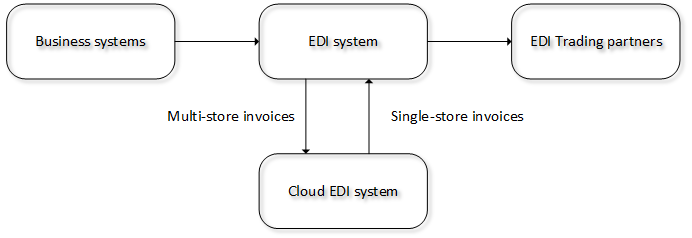

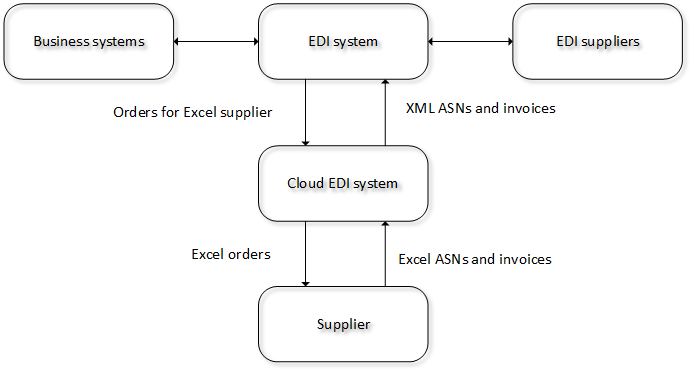

The remaining 5% of potential projects tend to never be delivered. Perhaps they involve potentially troublesome formats like Excel spreadsheets or PDFs, or new software needs to be developed perform some task that’s beyond the scope of the EDI system.

They never come to fruition usually because the return on investment wouldn’t be good enough, but that needn’t be the case.

With the right tools working alongside your existing EDI system, a good part of that 5% can be delivered at a cost that finally makes them a practical proposition.

In this article, I’ll describe some real-world scenarios where this was the case.